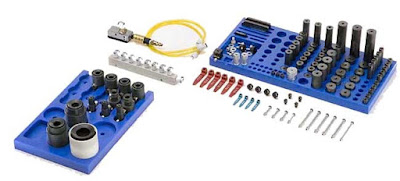

It is the small tools of best clamping kits that carry replenishment of perfect product manufacturing. The mechanics get the opportunity to hold brass, plastic, titanium, aluminum, ferrous and non-ferrous parts accurately and work is done in full potential. Moreover, the senior managers get access to evaluation of all steps of production and erase all kinds of mistakes. The vast variety of plates and threads satisfies everyone’s needs. Aluminum fixture plates are toughest plates in the market and its 4 types of threads i.e. ¼-20, M4, M6, M8 make it easier to use in most of the projects of production.

The staff gets the facility to do fixture at perfection with the use of best clamping kits. For mounting on rotary tables or stages; round plates are used. It also minimizes breakage or damage to metallic inputs and less depreciation leads to more profit for the manufacturer. Now the manufacturer is not supposed to invest more money. The favorable conditions due to the use of reliable tools automatically result in the making of more chips and plates. Hence, it informs every mechanic about the notability of the small step of production.