The

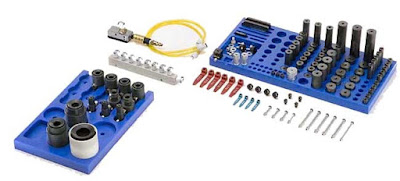

competence value of small tools of best clamping kits makes it worthy to build a sound fixture. This soundness further paves the way of producing the intact

finished product. No manufacturing industry can exist without it. The

easiness in holding pieces for routing, sanding, carving and much more brings

efficiency in the production process and saves a lot of time. The saved time

can be utilized for other testing specimens. Such small tools carry a lot of

wonders that all models of fixture plates become long lasting and reusable. Its valuable feature allows bowls, platters, and lids

without leaving any tool markings.

This is

designed keeping in view the economic aspect of manufacturers. The accuracy,

reliability, precision brought by best clamping kits create security for launching other services in the

manufacturing unit. These are available in four

sizes i.e. R20 (with ¼-20 thread size), R8 (with M8x1.25 thread size), R6 (with

M6x1.00 thread size) and R4 (with M4x0.70 thread size). It is up to the

manufacturer to obtain the best possible results and collect worthy revenue for

unexpected financial loss in the near future. The best part of it is that even an

unskilled mechanic gets the atmosphere to complete the work in an efficient

manner.